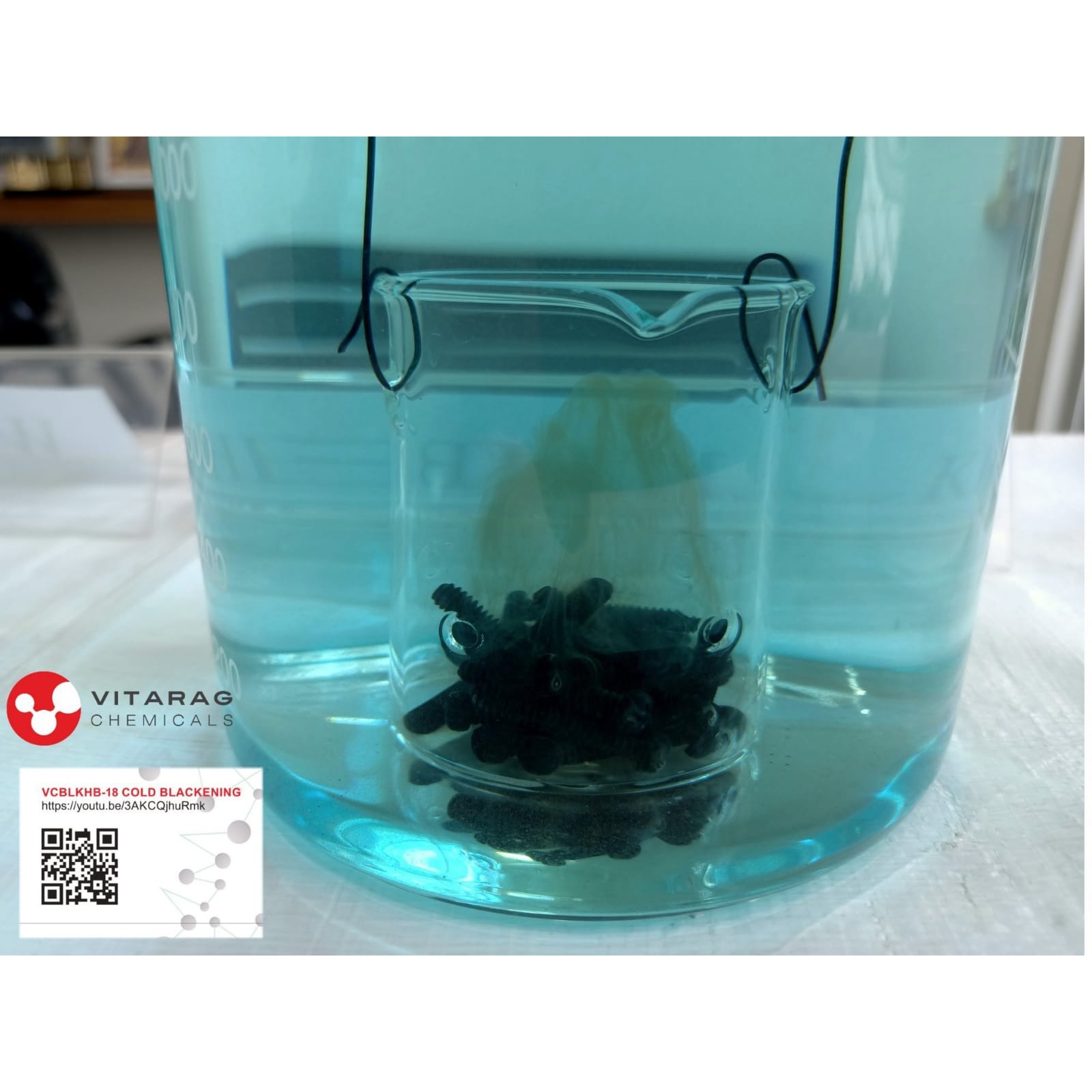

Blackening Chemicals Guide - Blackening, also known as black oxide coating or blackening treatment, is a process used to coat metals with a dark, corrosion-resistant layer. This finish is commonly applied to ferrous metals (like steel and iron) but can also be applied to copper, brass, and zinc. The process is popular in the manufacturing, automotive, and firearms industries due to its ability to enhance appearance, reduce light reflection, and improve corrosion resistance. - Here’s a guide to the blackening process, including the types of chemicals used and the procedures involved: - Types of Blackening Processes 1. Cold Black Oxide: - Suitable for steel, iron, copper, and brass. - Involves room temperature chemical baths. - The finish is not as durable as hot black oxide but is simpler and safer to apply. - Common chemicals used: copper selenium compounds, which form a black copper selenide layer.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry